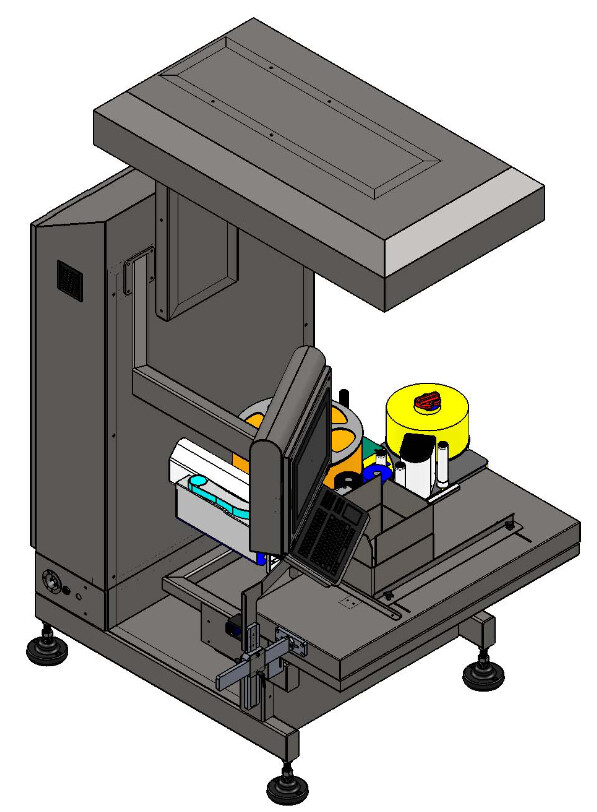

U-Pack SCG2-PA

| General Description |

The U-Pack SCG2-PA (Print and Apply) is an automatic label application and camera inspect portable Pack By Layer (PBL) aggregation module that provides no-tools, quick change over and adjustable solution to the multi-line packaging industry’s needs. The U-Pack SCG2-PA was designed by a multidisciplinary team of specialized engineers in the material handling, controls, safety and ergonomics fields to produce a robust machine for any case serialization requirements. Applications: Bottle, carton or bundle aggregation to a shipper |

|

| Machine Highlights |

|

|

| Overall Machine Footprint |

|

|

| Pack By Layer | Pack by Layer with top camera mounting and high resolution camera cover | |

| Machine Flow Direction | Left to right or Right to Left |

|

|

Carton Dimensions: L(dimension parallel to movement)-W-H

|

|

| Material Secondary (Shipper Case) |

|

|

Item Inspection Specification |

|

|

|

|

|

|

| Case Label Dimensions

|

Width/length: 2.0” to 4.5” / 2.0” to 11.8” (50 to115mm / 50 to 300mm) | |

| Output | Operator Dependent | |

| Utility Requirements |

|

|

| Structural System |

|

|

| Ergonomic Station |

|

|

| Printing Systems | Video Jet 9550 Print & Apply with Printer Mounting and Set-Up |

|

| Electrical / Controls |

|

|

| Documentation |

|

|

| Language | English | |

| Warranty | 1 Year | |

| Assumptions |

|