Categories

U-Pack SCSA

SKU SCSA

$62 763.00

Systech Hardware

Structural

Conveyor

Documentation

Printers Thermal Transfer

Printers TIJ

1

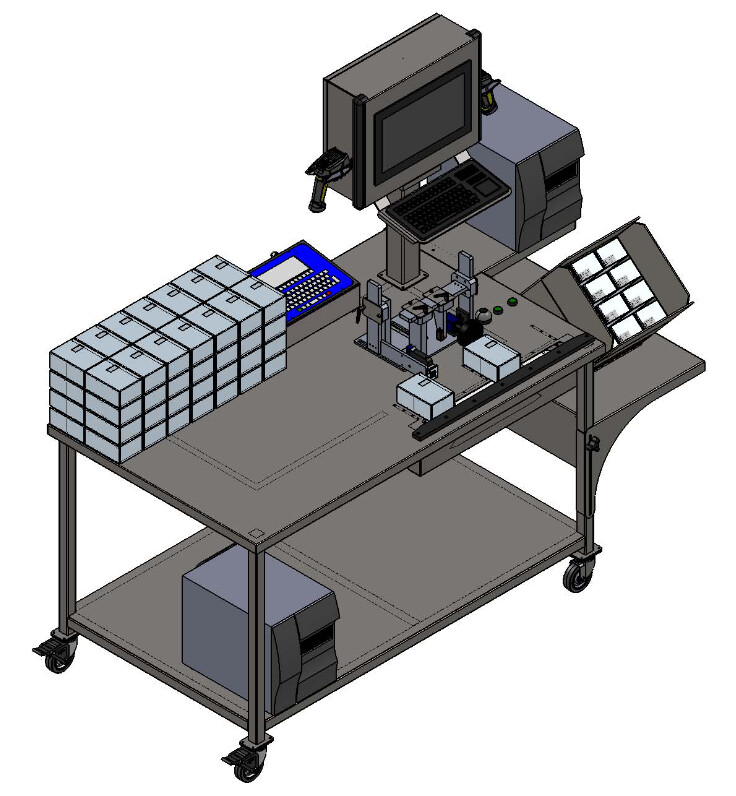

U-Pack SCSA

Product Details

General Description: Manual Packing serilization and aggregation for high mix low volume production that manages all aggregation levels from L1 to L4

Machine Interphase: Systech Native HMI for Machine Control

Printer: Wolke M600 OEM and 2 Zebra ZT400 with Printer Stand

Highlights: Portability, Ergonomy and Safety

Systech Unisolve: Serialization Ready

Documentation: Serialization and Validation Packages Available

| General Description |

An ergonomically designed equipment for low volume high mix production able to serialize and aggregate packaging level 1 through 4 in one portable machine. The U-Pack SA equipment was designed with the operator and management in mind. The operator achieves serialization and aggregation of Packaging Level 1 units in one arm motion, providing a fast and safe manual process. Management achieves higher serialization and aggregation throughput with minimum investment. Also, the U-Pack SCSA is equally at ease with very small lot sizes as well as large ones; change-over can be performed in less than 5 minutes.. |

|

| Machine Highlights |

|

|

| Overall Machine Footprint |

|

|

| Machine Flow Direction | Left to right or Right to left |

|

|

Carton Dimensions: L(dimension parallel to movement)-W-H

|

|

| Material Secondary (Shipper Case) |

|

|

Item Inspection Specifications |

|

|

Label Inspection Specifications |

|

|

| Case Label Dimensions

|

1.00"/25.4 mm to 4.5"/114 mm tear/cutter | |

| Output | Operator Dependent | |

| Utility Requirements |

|

|

| Structural System |

|

|

| Ergonomic Station |

|

|

| Printing Systems |

|

|

| Systech HW |

|

|

| Electrical / Controls |

|

|

| Documentation |

|

|

| (Internal QC Check) | This document will include basic machine function testing that will includes IO’s, wiring check, alarm testing and a 5 min run for the class and product selected by the client. Documentation will be executed following GAMP 5 compliance. | |

| Language | English | |

| Media | Hard copy binder with a disk containing the electronic manual |

Display prices in:USD