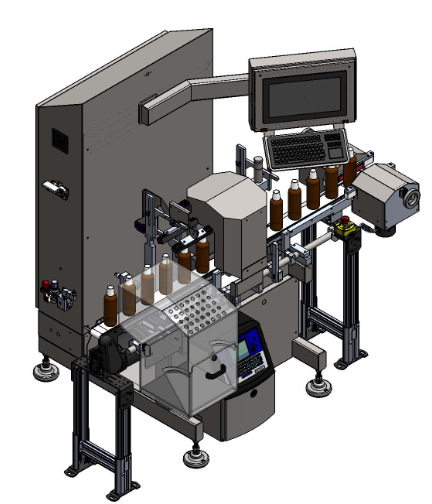

U-Read TG2

| General Description |

The U-Read 360 (Standard) provides a 360° inspection of a Data Matrix code on a round un-oriented bottle. When the bottle to be inspected enters the Cognex scanners arrangement, the system software searches for the Data Matrix code. Once the Data Matrix code is detected, the system reads the code and the Systech Sentri sends the results to the Systech Advisor to be processed. The bottle label 2D code detected is associated to the top or bottom code with an additional camera located out of the scanners arrangement. This solution is used when round bottles need to be aggregated to bundles or shippers using a top or bottom aggregation camera on a downstream machine or additional aggregation module.

This unit provides an ultimate solution since is a portable and convenient equipment for the packaging operations that intends to serialize products in more than one packaging line. |

|

| Machine Highlights | Portable compact design | |

| Enclosed and secured serialization process | ||

| Audible and visible alarms | ||

| Interface access levels | ||

| Serialization ready | ||

| Ergonomically designed | ||

| Multi size bottles | ||

| Overall Machine Footprint | Length (A): 2009.78 mm - 79 1/8" Depth (B): 1365.25 mm - 53 3/4" Height (C): 1790.70 mm - 70 1/2" Conveyor Height: 914.40 mm - 36" Monitor Height: 1517.65 mm - 59 3/4" |

|

| Machine Flow Direction | Upak Part Number (UPN): 360-S-1C Left to right (shown right to left) | |

| Material Primary (Round Bottles) |

Bottle Dimensions: Diameter x Height

|

|

| Output | Up to 200 bpm Manual Feeding (maximum speed dictated by operator) |

|

| Utility Requirements | Voltage: 3 phase 208 VAC ±10% - 60Hz | |

| Amps: 30 amps | ||

| Air: 75 PSI on 3/8” ID tube – 1 cfm | ||

| Noise: <75 DB | ||

| Safety | UPN 360-S-01A ISO 13849-1:2006 Category 3 safety compliant | |

| Structural System |

UPN 360-S-02A Stainless steel frame 2" X 2", stainless steel and anodized aluminum construction |

|

| Feeding System | UPN-360-S-05B Synchronized dual side belt |

|

| Conveyor System | Flat belt conveyor with belt speed up to 100 ft/min. Anodized aluminum construction and urethane white endless belt | |

| Product Guides |

UPN-360-S-06C Side guides with quick adjustment and position feedback |

|

|

Data matrix minimum module size: 0.25 x 0.25 mm Data matrix symbol size: 16x16 to 26x26 1D barcode thin-bar width (min): 0.167 mm Text character height: 1.30 mm |

|

| Camera Brackets | Camera mounting with Y and Z quick adjustment and position feedback | |

| Printer Brackets | Printer mounting with Y and Z quick adjustment and position feedback | |

| Reject Systems |

|

|

| Electrical Panel | Stainless steel panel with main power disconnect | |

| HMI | SS HMI enclosure with service ports Avantech computer 15" monitor USB and ethernet ports |

|

| PLC Allen Bradley CompactLogix | High-speed counter modules | |

| Combination of digital and analog counter integrated | ||

| Controller tasks | ||

| Built-in communications ports | ||

| Ethernet/ IP node | ||

| Access to DeviceNet network | ||

| Embedded I/O modules | ||

| Network | Stratix 2000 Switch, Unmanaged, 8 Copper Ports | |

| VFD | PowerFlex 525 AC drive, with embedded etherNet/IP and safety | |

| Control Panel Push Buttons | Start – To start the system | |

| Stop – To stop the system | ||

| Reset/Acknowledge- To reset/remove an alarm or fail condition on the control panel and to acknowledge an alarm. | ||

| Safety Reset - To reset safety circuit after an Estop event and to reset safety circuit after a guard door open. | ||

| Emergency Stop - One (1) illuminated red, twist-‘n’-release emergency stop pushbutton and to shut off power to the U-Read system. | ||

| Sensors | Photo switch Photoelectric Sensors (trigger, tracking, reject verify, reject station and bin full) Pressure switch sensors (compress air low) |

|

| Fail Safe | All electrical components fail safe hardwire and programmed | |

| Power Failure Condition | In the event of a power failure, the operator must remove all the cartons inside the machine. Once the machine is cleared, the system can be re-started following the normal procedure. | |

| Operation with disabled Vision Inspection System | Operation of the machine with a disabled Vision Inspection System can only be initiated by personnel with Administrator level, which will disable the Vision Inspection System from the Systech HMI. When this is done, the entire machine control is transferred to the machine’s HMI. Start of a new lot is done from the machine HMI. Once the cartons leave the printing station, they continue their travel directly to the Good Product area unless an alternate alarm occurs. | |

| E-Stop Condition | In the event the machine is stopped using the E-Stop button, the system’s safety circuit release all source of energy of the machine and brings them to a safe condition. In this situation, the cartons correct alignment on the conveyor is compromised. Once the E-Stop is deactivated and alarms cleared, the machine can be re-started. | |

| Critical and Non Critical Alarms | The U-Read alarms will be programmed in the U-Read PLC and will be managed from the Systech HMI. In cases when the Systech Vision System is disabled, all the alarms will be displayed and controlled from the machine HMI. Alarms will indicate any abnormal condition in the machine and guarantee an operator action | |

| Documentation |

|

|

| (Internal QC Check) | This document will include basic machine function testing that will includes IO’s, wiring check, alarm testing and a 5 min run for the class and product selected by the client. Documentation will be executed following GAMP 5 compliance. | |

| Language | English | |

| Media | Hard copy binder with a disk containing the electronic manual |