U-Track FCG2-L -C

| General Description |

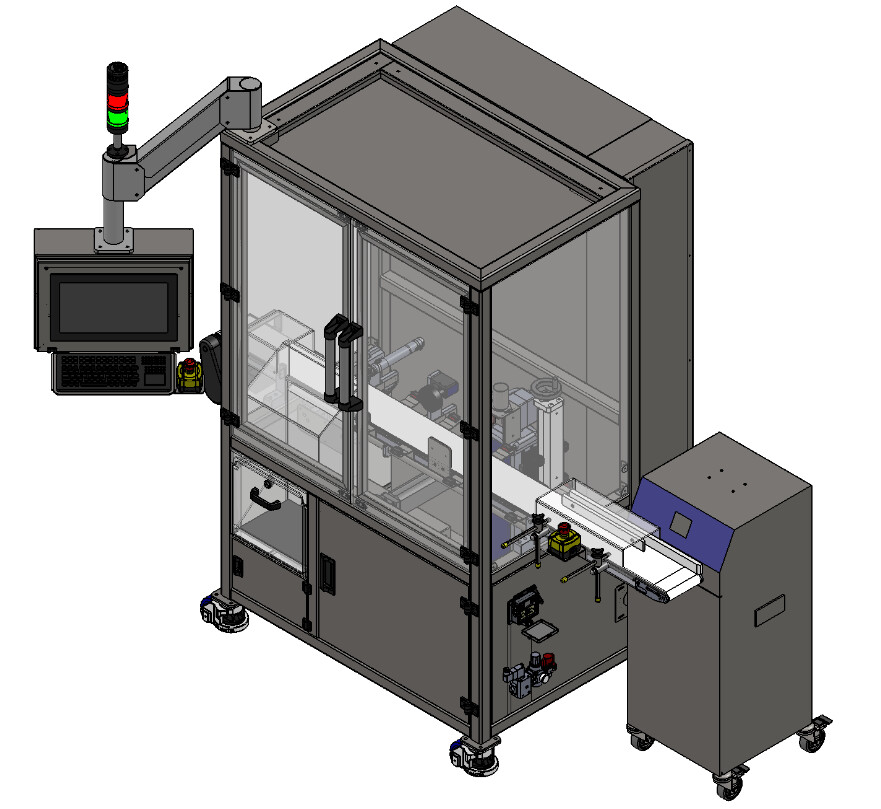

The U-Track FCG2 is a print and inspect contained module specially designed primary package serialization the process required by small to large production lot sizes. This unit provides an ultimate solution since is small and portable equipment for the packaging operations that intend to serialize products in more than one packaging line. This off-the-shelf machine provides everything required for the utmost control and safety on the serialization process, even the most demanding operation will find all its requirements met by the FCG2. The U-TRACK FCG2 offers a viable option for the entire pharmaceutical industry, including the CMOs. Ultimate Solutions and Systech have defined, integrated, and tested this unit to provide fast delivery, reduce deployment risks and control in-project engineering costs. This solution has an integrated user interface that allows the user to navigate the Systech and machine controls alarms from the same environment. The U-TRACK FCG2 is backed by Systech and Ultimate Solutions services and support teams for expert deployment and ongoing support. Applications:

Products:

|

|

| Machine Highlights | Portable compact design |

|

| Enclosed and secured serialization process | ||

| Audible and visible alarms | ||

| Interface access levels | ||

| Serialization ready | ||

| Ergonomically designed | ||

| Multi-size folded carton | ||

| Overall Machine Footprint | Length (A): 2133.60 mm - 84" Depth (B): 1003.30 mm - 39 1/2" Height (C): 2292.35 mm - 90 1/4" Conveyor Height: 914.40 mm - 36" |

|

| Machine Flow Direction | Left to right | |

|

Carton Dimensions: L(dimension parallel to movement)-W-H • Minimum: 50.8 mm x 25.4 mm x 12.7 mm [2" x 1" x 1/2"] • Maximum: 203.2 mm x 203.2 mm x 152.4 mm [8" x 8" x 6" ] |

|

| Output | Up to 200 CPM Automated Feeding Up to 20 CPM Manual Feeding (maximum speed dictated by the operator) |

|

| Utility Requirements | Voltage: 1 phase 120 VAC ±10% - 60Hz | |

| Amps: 40 amps | ||

| Air: 75 PSI on 3/8” ID tube – 1 cfm | ||

| Noise: <75 DB (not including air blow off noise) | ||

| Structural System | Stainless steel frame 2" X 2", stainless steel, and anodized aluminum construction |

|

| Machine Guarding | Enclosed operation | |

| Feeding System | Synchronized dual side belt |

|

| Conveyor System |

Side belt machine conveyor with the belt speeds up to 100ft/min |

|

| Product Guides | Side guides with quick adjustment and position feedback |

|

|

Domino 320i Laser • SIDE B • Encoder • Mounting Adjustments |

|

|

• Data Matrix Minimum Module Size: 0.25 x 0.25 mm • Data Matrix Symbol Size: 16x16 to 26x26 • 1D Barcode Thin-Bar Width (min): 0.167 mm • Text Character Height: 1.30 mm |

|

| Inspection Brackets |

Camera mounting with Y and Z quick adjustment and position feedback | |

| Printer Brackets |

Printer mounting with Y and Z quick adjustment and position feedback | |

| Reject Systems | Lockable reject station Air blow-off carton ejection Manual regulation for blow off eject pressure adjustment |

|

| Electrical Panel | Stainless steel panel with main power disconnect | |

| Fail-Safe | All electrical components fail-safe hardwire and programmed | |

| Power Failure Condition | In the event of a power failure, the operator must remove all the cartons inside the machine. Once the machine is cleared, the system can be re-started following the normal procedure. | |

| Operation with disabled Vision Inspection System | Operation of the machine with a disabled Vision Inspection System can only be initiated by personnel with Administrator level, which will disable the Vision Inspection System from the Systech HMI. When this is done, the entire machine control is transferred to the machine’s HMI. The start of a new lot is done from the machine HMI. Once the cartons leave the printing station, they continue their travel directly to the Good Product area unless an alternate alarm occurs. | |

| Operation with disabled Printer | Operation of the machine with a disabled printer can only be initiated by personnel with Supervisor or above level, which will disable the printer from the machine HMI. The machine can be run using pre-printed cartons. In this condition, the Printer Trigger Sensor is disabled and the cartons continue their travel to the Systech Vision Inspection Station where they are inspected following the normal system sequence. | |

| E-Stop Condition | In the event the machine is stopped using the E-Stop button, the system’s safety circuit release all source of energy of the machine and brings them to a safe condition. In this situation, the cartons correct alignment on the conveyor is compromised. Once the E-Stop is deactivated, alarms, and products cleared, the machine can be re-started. |

|

| Critical and Non Critical Alarms | The U-Track alarms will be programmed in the U-Track PLC and will be managed from the HMI. Alarms will indicate any abnormal condition and guarantee an operator action |

|

| Documentation |

|

|

| Language | English | |

| FAT and SAT | 1. Automation and FE Systech Services for five (5) Days during FAT 2. Automation Services for ten (10) Days during SAT. 3. FE Systech Services for fifteen (15) Days during SAT. This will be billed on a Times and Material basis. |

|

| Video Link | U-Track FCG2-L Video |

|

| Warranty | I Year (Refer to Ultimate Solutions and Amgen Master Service Level Agreement) | |

| Assumptions |

|